Tunnelling: Today’s TBMs do it all

10 July 2020

There is a host of different equipment and machinery used to help build tunnels for roads, railways, pipelines and more, but there is no doubt which of these machines catches the eye and the imagination the most. Gigantic tunnel boring machines (TBM) are intricate assemblies of several systems working in perfect conjunction with each other.

Their diameter ranges from 1 meter to 20 meters and they can cut clean through rocks, sometimes along with creating concrete shields around the bored tunnels.

Understandably, the TBM market is largely driven by government spending on road and railway infrastructure. Countries such as China, Japan, Italy, South Korea, Norway, and Germany have vast tunnel networks that connect major cities within the country and sometimes internationally across borders, optimising transportation costs and boosting commerce.

According to a digest of a report on the Tunnel Boring Machine Market from Transparency Market Research, the equipment can be divided into hard rock TBM, soft rock TBM, and dual mode/custom TBM. Different cutting heads are used, depending on the type of rock. Similarly, other sub-systems used also vary, such as conveyer systems, cutting fluids systems, and shielding systems.

The hard rock TBM segment can be sub-categorised into open TBM; gripper TBM; double shield TBM; and single shield TBM.

Similarly, the soft rock TBM segment can be split into earth pressure balance (EPB) TBM and slurry head TBM. Slurry head TBM is more suitable when the water content in the rock is high. The dual mode or custom TBM are specially designed for a specific terrain and rock type.

Based on application, the TBM market can be segmented into traffic tunnelling and utility tunnelling. The traffic tunnelling segment is divided into road tunnelling and railway/metro tunnelling, while the utility tunneling segment can be classified into water and sewage, hydropower, and pipelines.

Asia Pacific is a key market for TBMs, due to the increasing government expenditure on infrastructure and rapid road and rail network expansion. Countries such as China, Japan, and South Korea have the longest total tunnel roads in the world, with the governments of China and Japan investing significantly in tunnels for faster commute between major cities. The topography of Japan and major parts of China is mountainous and hilly, so tunnels play an important role in the construction of road and rail.

Europe follows Asia Pacific in the global TBM market. Demand is high in the hilly terrain of Italy, Spain, and France. Countries such as India, Brazil, and South Africa have started increasing their expenditure on roads and railway networks, and this is anticipated to create substantial opportunities.

A project in the key market of Asia was recently announced with news that Balfour Beatty’s 50:50 joint venture, Gammon Construction, has been awarded a HK$7.2 billion (US$940 million) contract to deliver tunnels and associated works for an automatic people mover (APM) and baggage handling system (BHS) at Hong Kong International Airport on behalf of Airport Authority Hong Kong.

The contract will see Gammon deliver two 1,800m-long eight-cell tunnel structures for the APM and BHS systems as well as all electrical and mechanical works for the tunnels.

The APM and BHS tunnels and the associated works form a major part of the Three Runway System project at the airport and will ultimately allow travellers to move between the new Third Runway Concourse and the expanded Terminal 2.

Gammon will deploy modular solutions for 75% of the electrical and mechanical works for the tunnels. In line with Balfour Beatty’s commitment to reducing onsite activity by 25% by 2025, this approach will see activities carried out off site to ensure enhanced health and safety and increased productivity.

One size does not fit all

Modern, industrially operating TBMs make it possible to construct underground routes that closely follow the ideal line. Mechanised tunnelling projects can be carried out and controlled safely, and can be adapted exactly to ground conditions, diameters, depths, gradients, curves, lengths and the topographic conditions along the route.

“Herrenknecht machines are tailored to satisfy the essential project-specific requirements,” says Cornelia Lietzau of Herrenknecht AG. “The TBMs used are precisely designed for the purpose in question in each case depending, for example, on the geology, hydrology, the diameter or the construction site circumstances. In addition, the Herrenknecht Group offers integrated technological solutions and services which are tuned to the specific conditions of use.”

A representative of the China Railway Construction Heavy Industry Corporation Limited (CRCHI) says, “by positioning non-standard, characterised and customised high-end equipment manufacturing and service, CRCHI provides customised solutions according to different engineering, geological conditions and customer requirements.”

CRCHI adds that the company has, “built the largest underground engineering equipment industrial base in the world and developed seven series of TBMs of more than 50 specifications, which satisfy the specialised needs of the global customs.”

Currently, the development of various special shield tunnelling methods and supporting equipment technologies for special engineering complex geological conditions is a major trend in the TBM sector, according to CRCHI.

“At present and in the future, the function integration of TBM is getting higher and higher. There are more and more dual-mode shield tunnelling projects with two or more TBM functions, and the automation and intelligence of the equipment are getting higher and higher.”

The use of TBM is always challenging due to the prevalence of complex geological conditions. CRCHI says the main ways to improve the working quality and efficiency include developing and implementing new technologies, such as drilling-CT advanced geological prediction technology, SSP acoustic wave soft soil detection system, overall condition monitoring technology of cutterhead and cutter, automatic cutter changing technology, and high-pressure main drive sealing technology, to name a few.

Custom crossovers

Also known as hybrid or dual mode machines, Crossover TBMs are custom-engineered for those whose projects include sections of hard rock, soft ground, boulders and more. Robbins Crossover TBMs can convert between EPB and hard rock modes, between slurry and hard rock, or between EPB and slurry.

Standing for a Crossover (X) between Rock (R) and EPB (E), the Robbins XRE has been designed and deployed on multiple projects that feature sections of both hard rock and soft ground. Using features of both EPB and single shield hard rock machines, the XRE has been used on mixed ground projects in Australia, Turkey, Mexico, India, and more.

According to Robbins, the XRE’s single-direction cutterhead cuts down on tool and machine wear and reduces the problem of regrind, which causes undue wear on machine elements. Two-speed gearboxes use power to generate high torque at low RPM, allowing the XRE to get through squeezing geology and fracture zones that might increase the chances of machines getting stuck.

At diameters over 12m, the XRE design becomes even more versatile, Robbins says. Current setups allow the belt conveyor to remain in place along with the screw conveyor, eliminating the conversion step between screw and belt. Instead, a hydraulic muck ring moves the conveyor into place if hard rock is encountered.

In urban environments with mixed ground conditions, settlement is not an option, and must be kept as close to zero as possible. The Robbins XSE TBM is designed to work in many of those cases.

In low-permeability soils without high hydrostatic pressures, the XSE is designed to advance quickly and efficiently in EPB mode without the expense and complication of slurry-based muck handling.

While in EPB mode, any slurry treatment plant on site can be simplified and made more economical. In EPB mode, the machine utilises a screw conveyor to maintain face pressure and remove muck. Because there is no slurry at the excavation face, any over-excavation is immediately apparent.

In high-permeability soils and areas with high hydrostatic pressures, however, the XSE can run in slurry mode, thereby eliminating the problems of inaccurate volume monitoring and pressure control that EPBs encounter in these conditions.

In terms of innovations, Herrenknecht’s E-Power Pipe technology enables tunnelling at smaller diameters for longer distances.

“With Herrenknecht E-Power Pipe in the small diameter range of about 500mm, it is now possible to realise ten times longer sections, of more than 1,000 meters,” Lietzau notes. “This technology was awarded with the Bauma Innovation Award 2019.

“The demand for increasingly long drives in smaller diameters leads to new technical solutions – to install tunnel systems and pipelines exactly where they are needed without harming the environment, while protecting above-ground structures.”

Digitalisation is the future

Like so many equipment sectors, companies involved in the complex drilling and boring into ground surfaces are focusing on ways to reduce and eliminate the vagaries of human error. As such, they’ve turned their attention to digitalisation to increase efficiency and high performance. Saipem, an Italian multinational oilfield services company, is one such company.

“The future of drilling passes through digitisation, along with the standardisation of the skills and proficiencies of operational personnel and multi-crew cooperation, are the focus of the future,” says Stefano Porcari, COO of Saipem’s Onshore Drilling Division. “The combination of these elements have a more than positive effect in a risky and complex environment such as a drilling platform.”

Considering onshore drilling a strategic activity, Saipem has recently launched a pilot project in Kuwait for the digitalisation of its drilling operations, which will involve benefits such as improving invisible downtime and safety performance, reducing GHG emissions and exploiting preventive maintenance and automation to enable operational efficiency.

“Our focus is to develop the full potential of our drilling systems by expanding into further activities, such as unconventional drilling,” Porcari says.

It will certainly be interesting to watch the continued evolution of this class of equipment which so much infrastructure development depends on.

Rock bolter offers more penetration

Rig designed for high levels of automation and more visibility

Swedish mining and rock technology manufacturer Sandvik offers the DS512i rock bolter designed for 5m by 5m headings.

Introduced late last year, Sandvik says the rig was designed specifically for tunnelling and mining and was developed based on a modularised concept, leading to high levels of parts commonality with the Sandvik DT922i to reduce the cost of ownership.

The machine is equipped with a new carrier, high frequency rock drill, control system and an enhanced cabin. According to Sandvik this gives it better levels of safety and efficiency.

Sandvik says the rig offers 35% higher penetration rates than its predecessor, and features an upgraded bolting head, with different bolt lengths, plus an eight-rock bolt carousel, allowing for the installation of bolts from 1.6cm to 6m in length.

An automatic resin-shooting and cement-mixing system further enhances the rock reinforcement process. The bolting head movement also has standard assistive and automatic features.

Challenging projects

Robbins TBMs tackle tough jobs around the world

Tunnelling is precarious business, as its difficult to ever really know exactly what challenges will be found underground.

In January 2020, a Robbins 5.97m diameter Main Beam TBM cleared its final hurdle when it broke through in Guangxi Province, China, after a series of

challenges including karst cavities to fault zones and water inflows.

The TBM excavated its first of two tunnels, an 11.9km long conduit for Lot 1 of the North Line Water Irrigation Project, Letan Water Reservoir, Drought-Relief. Those on the jobsite – contractor Guangdong No. 2 Hydropower Bureau, and the owner, Construction Management Bureau for the Letan Water Reservoir – had much to celebrate after completion of what is widely regarded the most complex and longest tunnel on the North Line project.

Located near Laibin City, the North Line project provides much needed drought relief using a network of tunnels totaling 29.4km.

On the other side of the world, where it isn’t drought but flooding to be dealt with, the City of Dallas, Texas, US recently unveiled the largest hard rock TBM ever to bore in the US. The 11.6m diameter Robbins Main Beam TBM is excavating the 8km Mill Creek Drainage Relief tunnel, and its size is not its only distinction. The adaptable machine will change size partway through the bore, to a more compact 9.9m.

The unique Robbins TBM is being used to dig a tunnel designed to provide 100-year flood protection for east and southeast Dallas, areas affected in recent years by severe storms.

The dual-diameter aspect of the Robbins TBM will be a first-of-its-kind conversion process. The Robbins TBM, named ‘Big Tex’ with permission of the State Fair of Texas, has been designed with a specialised cutterhead including removable spacers and adjustable bucket lips to convert to a smaller diameter.

The TBM will first complete its 11.6m diameter section of the alignment, then back up about 21m to a transition area

for the conversion, which is expected to take six to eight weeks.

The project is expected to be completed on schedule in 2023.

US$893 million Paris project

More than one million cubic meters of material will be excavated

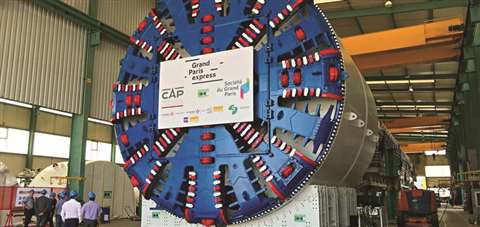

A joint venture of the French contractors Vinci Construction and Spie Batignolles has been awarded a US$893 million contract to work on Line 18 of the Grand Paris Express, by the Société du Grand Paris (SGP), requiring almost 12km of tunnel.

The Grand Paris Express project is reportedly the biggest urban mobility project currently underway in Europe and will see the development of four rapid transit rail lines (lines 15, 16, 17 and 18) within the Ile-de-France region of France.

The Line 18 project will use two tunnel boring machines, and involve the construction of three new stations, 13 ancillary engineering structures, ten branches connecting with the tunnel, and 850m of cut and cover. In total, more than one million cubic meters of material will be excavated.

The Line 18 will allow passengers to travel from Orly Airport to Versailles Chantiers within 30 minutes, according to reports. Line 18 to Versailles will be opened in 2030, when it will have ten stations serving some of south west Paris’ most strategic hubs.

The entire line will have 21km of underground and 14km of elevated sections, crossing Plateau de Saclay. Line 18 will provide passengers transport connections at Orly Airport, Massy Palaiseau and Versailles Chantiers.