APi to supply scaffolding to shipyard on Lake Superior

21 November 2023

Fraser Shipyards has been in continuous operation since 1888

Fraser Shipyards has been in continuous operation for 135 years on the shores of Lake Superior. (Photo: Fraser Shipyards)

Fraser Shipyards has been in continuous operation for 135 years on the shores of Lake Superior. (Photo: Fraser Shipyards)

APi National Scaffold has agreed to a contract to supply state-of-the-art scaffold equipment for a construction project at Fraser Shipyards in Superior, Wisc., on the shores of Lake Superior.

APi Construction Scaffold Division Manager Russ Byers said construction crews will deploy MonZon’s PROTECT IT weather protection system, which is designed to protect workers and projects from extreme weather.

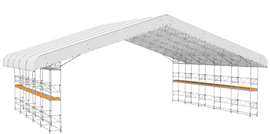

As the exclusive U.S. distributor of MonZon’s system, APi National Scaffold is experienced in designing and installing the weather protection apparatus, which is made of recyclable aluminum and allows for design flexibility with asymmetrical/symmetrical, double-pitched/mono-pitched and mansard spans.

“This project has an aggressive timeline, and our teams are already working efficiently to ensure this project is an all-around success,” Byers said.

Fraser Shipyards, which has been in continuous operation since 1888, will build a new 150-passenger ferry under the weather cover, and the project’s productivity and schedule will be enhanced by the renovation while being unaffected by weather conditions.

“We chose the PROTECT IT system because it allows a contained and safe shipbuilding process for our team with its strength and design flexibility,” said Chad DuMars, head of New Build Construction at Fraser Industries. “We’re looking forward to working with APi National Scaffold and to see the efficiencies this system will bring to our operations.”

MonZon’s PROTECT IT weather protection system (Photo: APi National Scaffold)

MonZon’s PROTECT IT weather protection system (Photo: APi National Scaffold)

The modular scaffolding solutions provided by APi are specifically tailored to meet the unique requirements of the shipbuilding process, and the PROTECT IT system includes a motorized retractable roof that can be adjusted to provide access to specific areas as the ship construction progresses.

APi said it will leverage its extensive experience and a proficient team of experts to ensure maximum worker safety and efficiency throughout the project’s duration.

“We’ve been working closely with Fraser to ensure our scaffold system design fits the unique needs of their ship construction and the weather elements at play,” said Tanner Vik, manager, APi National Scaffold. “Our team is committed and ready to safely execute this project from start to finish.”

Both API National Scaffold and Fraser Shipyards said this project will further advance the U.S. shipbuilding industry and contribute to the regional and national economy, and the construction of this ferry and other new builds and repair work at the shipyard will generate employment opportunities and support manufacturing, logistics and ancillary services.