The effort to make diesel engines cleaner in the future

26 June 2024

Diesel engines have been the workhorses of off-highway equipment for decades. Ever-evolving emissions regulations around the world have made them significantly cleaner running than they once were. However, with today’s focus on sustainability, many question the future role these engines will play in the drive to sustainability and decarbonization.

According to Michael Lefebvre, manager of global marketing and product strategy at John Deere, one can look at the future of diesel engines — and internal combustion (IC) engines overall — through two different lenses: clean technology and efficiency.

“Both are critical when it comes to the continued viability of internal combustion engines as part of the sustainability journey we’re on as an industry,” Lefebvre said.

Regarding clean technology, Lefebvre said engine makers will build upon their successes in reducing diesel engine emissions to find ways of reducing them even further.

“For example, with advancements in technology, such as selective catalytic reduction (SCR) and diesel particulate filters (DPF), we’ve seen some significant reductions in emissions of nitrogen oxides (NOx) and particulate matter,” he said.

According to Lefebvre, the industry is particularly focused today on improving diesel engine fuel economy while also reducing carbon dioxide (CO2) emissions. Deere said that its engines have been designed for low emissions without sacrificing performance.

Michael Lefebvre, manager of global marketing and product strategy at John Deere. (Photo: John Deere)

Michael Lefebvre, manager of global marketing and product strategy at John Deere. (Photo: John Deere)

While John Deere is investing in low- and near-zero emissions technologies, such as battery electric, hybrid and renewable fuels, the company said it is also taking steps to advance performance and efficiency in diesel engines.

That means developing solutions that will create new value for customers while avoiding disruption in the adoption of those new technologies, Deere said. For instance, when developing its JD4, JD14 and JD18 industrial engines — the company’s latest — Deere said it consulted equipment OEMs to understand what engine improvements were a priority for them.

Addressing Efficiency

“There are opportunities for us to make diesel engines even more efficient through optimized engine design, improved combustion systems and engine rightsizing — ensuring that the right engine size or power unit size is being used in an application,” Lefebvre said.

He added that this approach helps maximize uptime, reliability and fuel efficiency.

“This will improve overall customer value, lower fuel consumption and in turn, reduce criteria pollutants,” Lefebvre said.

Ultimately, Lefebvre said he believes diesel engines will continue to play a role in off-highway equipment. IC engines coupled with advancements in battery power and renewable fuels will help the industry navigate the power landscape of the future, he said.

Role of Hybrids

UK-based engine manufacturer Perkins is also investing in unique IC technology. In particular, its focus is on smaller OEMs with more limited resources, which Perkins said it believes play a part in the energy transition.

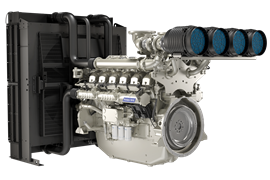

Perkins is collaborating with Equipmake and Loughborough University to develop and produce an advanced multi-fuel “drop-in” hybrid integrated power unit based on the 7 L Perkins 1200 Series. (Photo: Perkins)

Perkins is collaborating with Equipmake and Loughborough University to develop and produce an advanced multi-fuel “drop-in” hybrid integrated power unit based on the 7 L Perkins 1200 Series. (Photo: Perkins)

In October 2023, Perkins announced it was collaborating with UK-based engineering firm Equipmake and the School of Mechanical, Electrical and Manufacturing Engineering at Loughborough University in the UK to develop an advanced multi-fuel “drop-in” hybrid integrated power unit.

Named Project Coeus — after the Greek Titan, god of resolve and intelligence, according to Perkins — the project will see the development of a power unit intended to be a direct replacement of its diesel counterpart in terms of power density and response. As such, it will be suitable for use by a wide range of off-highway OEMs regardless of size or application and will help accelerate their transition to lower-carbon intensity or zero-carbon as well as capitalize upon electrification.

“We are pleased to have secured this opportunity to accelerate the development of advanced off-highway power system solutions,” said David Goldspink, Perkins vice president and general manager.

“This project will explore, innovate and lead the way to solving some of the key challenges facing the off-highway industry’s energy transition and support the transition towards reduced carbon in this key sector.”

The initial demonstration of the power unit focused on hydrogen, but it will ultimately be suitable for a variety of fuel types, Perkins said.

Hybrid power systems will play a key part in decarbonization, as many off-highway applications have high energy demands that make it impractical to implement a full battery electric solution. With hybridization, OEMs can reduce carbon emissions via a solution that uses both an engine and electrification.